Usually, when I upgrade, it’s beneficial in some way. It improves performance, increases the strength of a part, or provides some other benefit. This upgrade, though, was for a different reason.

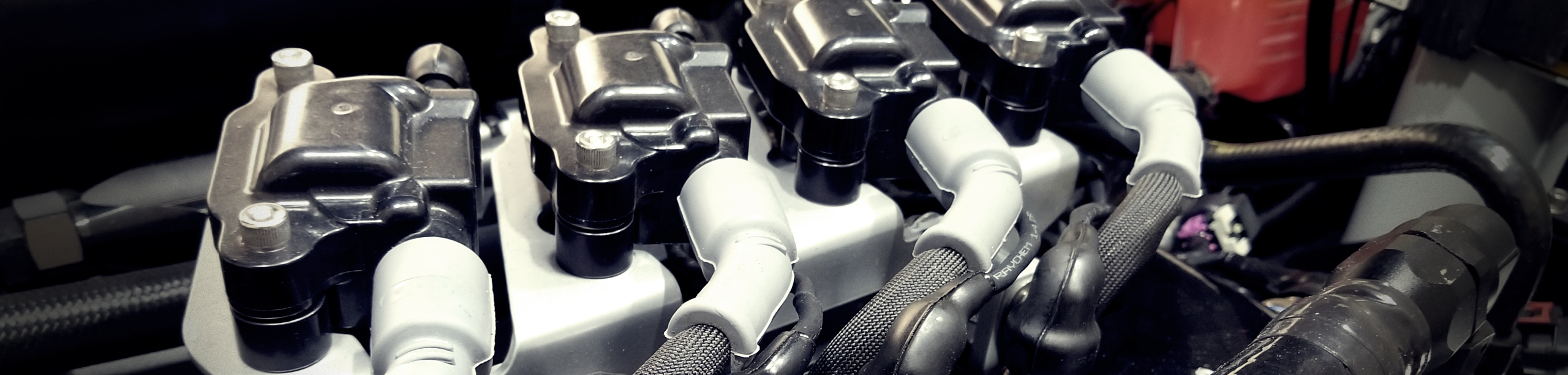

Scrolling through Instagram, I kept seeing pictures of Cruze engines with individual coils mounted over the cam cover. They looked really fricking cool, so I started searching. The kit wasn’t difficult to find since the cam cover plate had a big BNR logo on it, which is for Bad News Racing. I found their site, found the kit, and then found the price. It was a little bit of an investment, so I wanted to first find out what sort of return I would get on this investment. I emailed my tuner to find out what sort of benefit I would get from the upgrade. His response was, “Absolutely nothing.” So, why pay that much money for something that has no performance benefit? Because it looks really fricking cool, that’s why!

It was difficult to justify paying that much, so I looked into ordering the coils and wiring them up myself. It wouldn’t be hard to do, but after pricing out all the parts and what it would take to make the brackets and cover plate, the price from BNR really wasn’t that bad. So, now I had my justification. Yes, that’s how my brain works.

Once I ordered and received the kit, the only thing I wasn’t happy with was the wiring harness that came with it. The harness came with black corrugated wire loom covering the wires. If there is one thing in this world I hate, it’s corrugated wire loom. I think it looks cheap, and with my OCD, I wasn’t going to be able to handle it. Other inexpensive options would give it a more professional look, such as an expandable braided sleeve or a split braided sleeve.

So, before installing the kit, I started removing the corrugated loom so I could install something I could live with. That’s when I discovered the second thing I wasn’t happy with. The OEM connector has seven wires. four ignition signal wires, a signal ground, 12v power, and a ground. Obviously, there is one ignition signal wire per coil, and then the other three wires, the signal ground, 12v power, and ground, are all shared by each coil, so they need to be spliced together.

The BNR harness has the wires spliced using solder. This is a debatable subject, but what I learned from the engineers when I was a race car driver was they never used solder in a wiring harness, especially in a high-vibration environment such as the engine bay. The issue isn’t the solder itself, the solder joint is very strong and stiff. The issue is if there is movement in the wires around the joint from vibration, for example, over time, the wires can break. What I decided to do is make a new harness and splice the wires together using open barrel splices.

After I finished with the harness, I was able to install everything. The installation is a piece of cake. 15 or 20 minutes tops. Once that was completed, I needed to get a tune update from my tuner, as the new coils require a change in the dwell time. That was it. I now had the really fricking cool coils mounted over the top of my cam cover.

DS